HUGO BECK: “WE PACKAGE YOUR WORLD”

TEXT: MARILENA STRACKE | PHOTOS: HUGO BECK

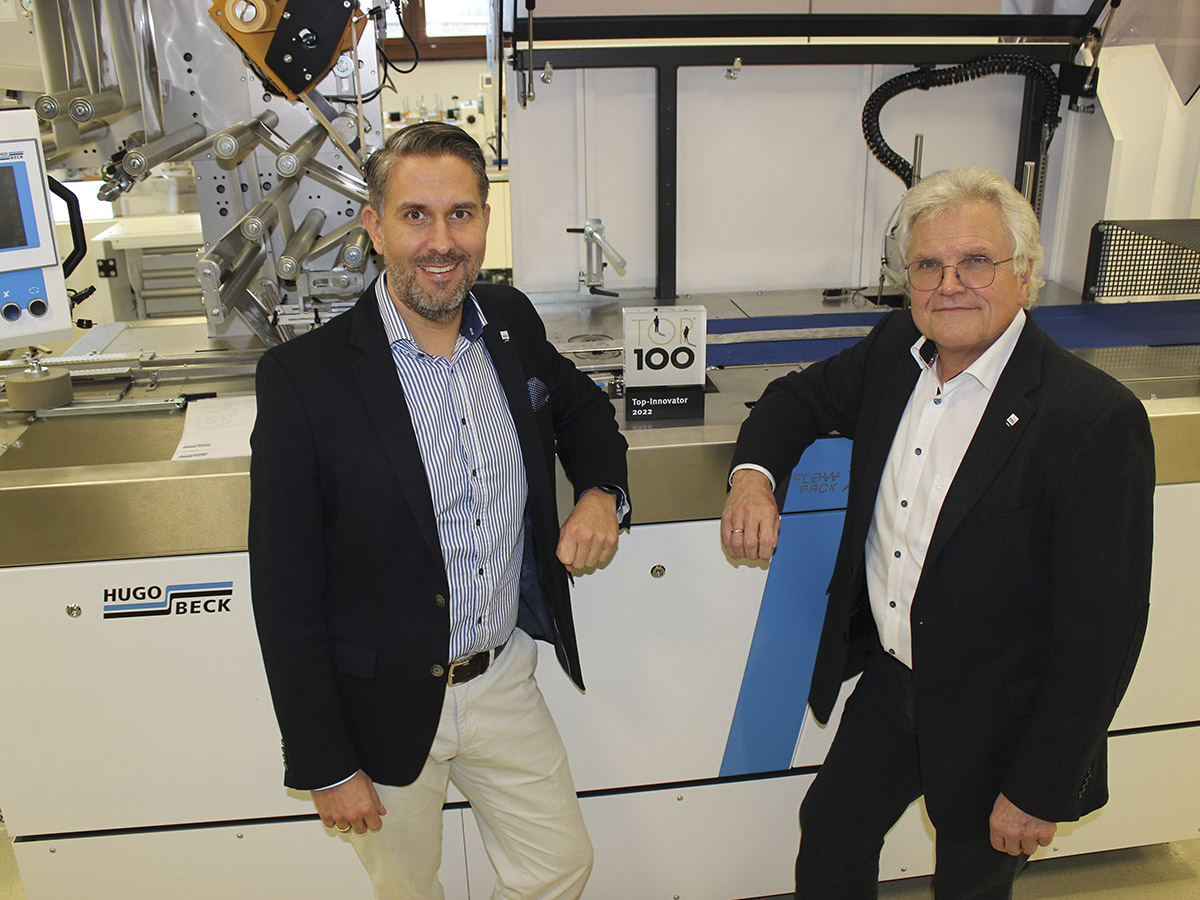

For the fourth time, the packaging machine specialist has received the ‘Top 100’ award, which honours the most innovative companies in the German SME sector. The award commends HUGO BECK’s success in innovation management and its achievements in developing sustainable packaging solutions. The image shows the Managing Directors Timo Kollmann (left) and Curt-Juergen Raiser (right).

The family business HUGO BECK develops and produces complete solutions for horizontal packaging in film and paper – all from a single source and for a wide range of industries and products. As a packaging machine manufacturer with over 65 years’ worth of experience, HUGO BECK leads the way and offers futureproof solutions that minimise the ecological footprint without compromising on quality.

In 1955, Hugo Beck founded his company as a workshop for turned parts, but by the early 1960s, he was already focusing on customised solutions with bespoke machinery, specialising in horizontal film packaging systems. From then on, the business steadily grew from a Swabian one-man operation to the world-leading specialist it is today. Now in its third generation, HUGO BECK is internationally renowned for developing and producing complete solutions for horizontal packaging in film and paper.

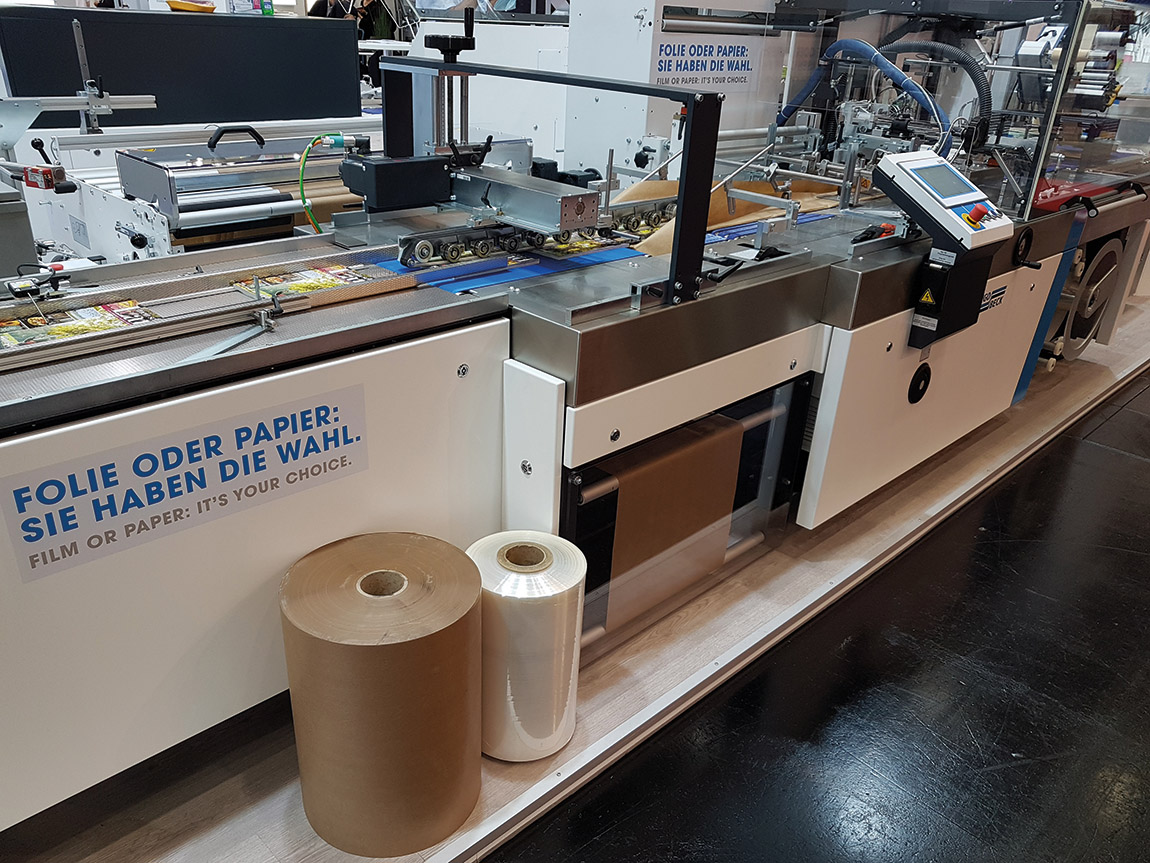

Film or paper? “It’s our customers‘ choice. We ensure our customers can select the best material according to their specific product application and sustainability objectives.”

“Our comprehensive machine range handles flowpacks, bags and shrink packs, as both primary and secondary packaging. HUGO BECK machines process all film types, independent of the manufacturer,” managing director Timo Kollmann explains. “This is enhanced by various paper packaging solutions, which underline our commitment to continual innovation in machine technology for sustainable packaging.”

Headquarters in Dettingen/Erms.

TAILOR-MADE MACHINES FOR YOUR PACKAGING NEEDS

The highest quality in packaging appearance, machine availability and efficiency speaks for itself, and has become highly valued among loyal customers. Tailored-made solutions are at the heart of HUGO BECK and the experienced team helps customers to find the ideal packaging for their specific industry and applications.

As Timo Kollmann points out, state-of-the-art in-house project planning and manufacturing processes are the prerequisite for being able to react flexibly to virtually all customer needs.

A classic product wrapped with resource-saving HUGO BECK machine technology: chocolate box in extremely tight-fitting film wrapped without any material waste during the packaging process.

He adds: “To make sure of this promise, we deliver everything from one source. We design and produce for our customers packaging solutions, either as a stand-alone system, or as a highly automated complete line – and we also safely integrate this into production environments. We provide both the hardware and software for the specific packaging application.”

Today, HUGO BECK packaging machines are in use worldwide and across many different sectors and for a multitude of products, volumes and packaging styles. The customer base ranges from the pharmaceutical industries and medical technology, to e-commerce and logistics, food, confectionery, household goods, cosmetics and hygiene products, to name but a few. HUGO BECK’s global presence and worldwide service deliver peace of mind for all customers across the globe.

Hermetically sealed flowpack packaging. Sterile products of different product dimensions and bundles are perfectly protected.

INNOVATIVE PACKAGING TECHNOLOGY FOR A SUSTAINABLE FUTURE

From the very beginning, HUGO BECK has been committed to operating in an environmentally responsible way. With the aim to not just meet today’s but also tomorrow’s requirements, it continuously works on innovative systems.

“In developing innovative machine technology, we aim to make packaging as resource-efficient as possible. From extremely tight packaging that minimises the use of film, to flexible machine solutions, which allow the production of film and paper packaging on just one machine or pure paper packaging machinery – we have various sustainability needs covered,” Timo Kollmann points out.

A recent development at HUGO BECK is a packaging machine which uses uncoated, recyclable paper which can then be sewed closed. This has proven popular in the e-commerce and mail order sector and has since been promoted as an innovation by Germany’s Federal Ministry of Economic Affairs and Energy.

“Our machines keep pace with the latest developments in sustainable materials. From the latest mono-material films or recycled content films to bioplastics or extremely thin packaging films, each can be applied using HUGO BECK technology,” Timo Kollmann explains. “Both uncoated and coated, recyclable papers are processed for paper packaging. We use resource-saving machine technology that minimises material consumption across the packaging process. Thus, only as much film or paper is used as is truly needed!”

For over half a century, the HUGO BECK name has been synonymous with the highest quality in horizontal packaging machines and that seemingly isn’t going to change any time soon.

Sustainable packaging: Resource-saving film and paper packaging machines from HUGO BECK minimise material use to deliver more sustainable packaging. A wide range of materials can be processed, including uncoated papers, bioplastics, recyclable mono-material and recycled content films.

Web: www.hugobeck.com

Subscribe to Our Newsletter

Receive our monthly newsletter by email